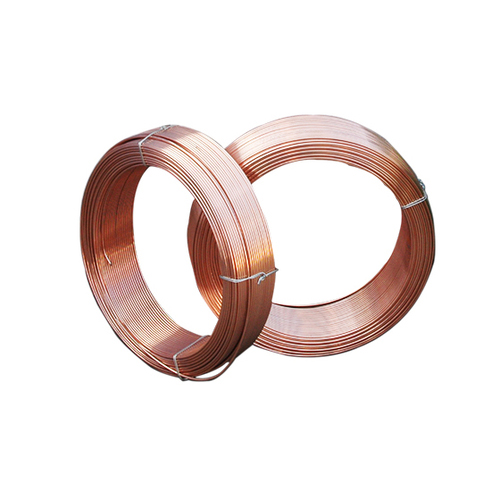

Submerged Arc Welding Wire Aws EL8 - A Welding Material with Excellent Performance and Reliable Quality

Hot melt welding is a welding method that uses an electric arc to heat and melt the welding electrode as a filler material, while gas shielded welding is a welding method that uses an electric arc to melt the welding wire and protects the welding area with argon gas to avoid oxidation. These two welding techniques are combined to form submerged arc welding. The Submerged Arc Welding Wire Aws EL8 is made of high-quality low-carbon alloy steel and is suitable for welding with carbon steel and low-alloy steel as base materials.

The Submerged Arc Welding Wire Aws EL8 has excellent arc stability and the ability to hang droplets one by one, ensuring stability and quality during the welding process. Its alloy composition is carefully configured to provide strong and durable welds in the welding of steel structures. Whether used for manufacturing ships, bridges, pressure vessels, or heavy machinery, AWS EL8 is capable of handling various demanding welding tasks.

This submerged arc welding line is very easy to operate, and both professional welders and beginners can easily get started. Moreover, AWS EL8 also has good formability and impact resistance, maintaining welding stability and reliability even in harsh environments.