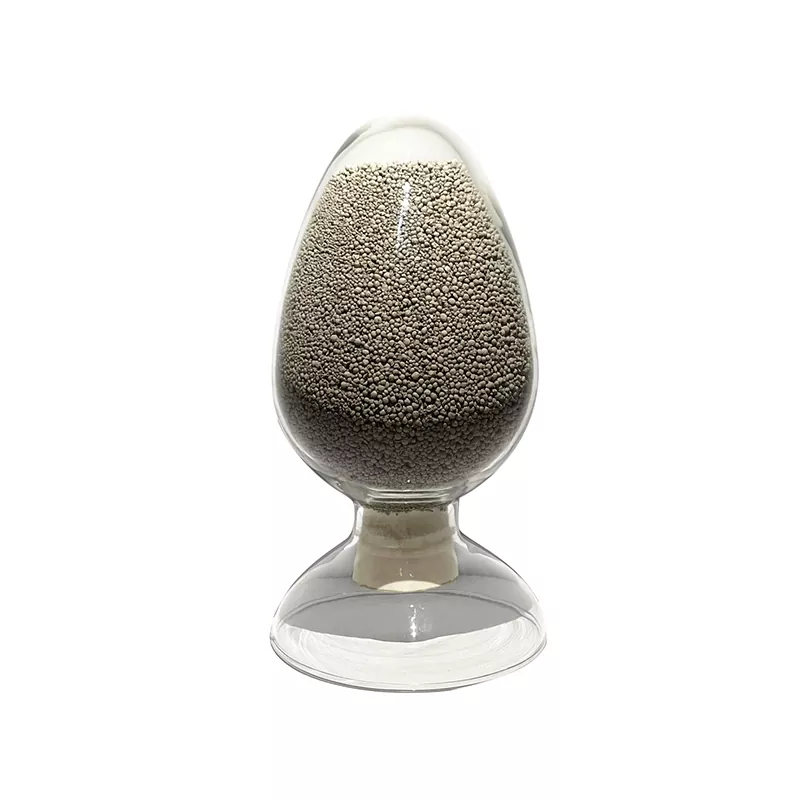

China Agglomerated submerged arc welding flux SJ501 Manufacturers, Suppliers, Factory

Every single member from our large efficiency profits team values customers' requirements and organization communication for Agglomerated submerged arc welding flux SJ501,SJ501 Welding flux,SJ501,Pipeline welding flux SJ501,Steel structure welding flux SJ501, In addition, we would properly guideline the shoppers about the application techniques to adopt our products and solutions as well as the way to select appropriate materials.

Agglomerated submerged arc welding flux SJ501, Our company always concentrate on the development of the international market. We've got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Hot Products

Welding flux SJ102

As the professional manufacture, GUJIN® would like to provide you Welding flux SJ102. And GUJIN® will offer you the best after-sale service and timely delivery.ER308L Stainless Steel

GUJIN® is one of the famous China ER308L Stainless Steel manufacturers and Stainless Steel suppliers.For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.ER309L Stainless Steel

GUJIN® warmly welcome you to wholesale ER309L Stainless Steel from our factory. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire Aws EL8

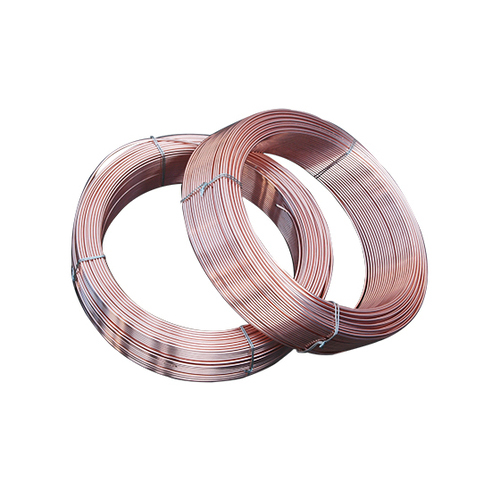

GUJIN® is a kind of low manganese low Submerged Arc Welding Wire Aws El8. It is matched with high manganese and high silicon type fluxes. Insensitive to rust on the base metal, excellent bead forming and slag separation. It is the most commonly used submerged arc welding wire. Monoles or dipoles. Can be used for AC/DC.Welding Wire EM13K

As the professional manufacture, GUJIN® would like to provide you Submerged Arc Welding Wire EM13K. For Submerged arc welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Submerged arc welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Submerged arc welding wire have characteristic design & practical performance & competitive price, for more information on the Submerged arc welding wire, please feel free to contact us.LPG Cylinder Welding Flux

SJ-501 submerged arc welding flux is an active aluminum-titanium type acidic sintered flux, designed for high-efficiency welding, providing stable arc combustion and excellent weld quality. The basicity index of this flux is approximately 0.5-0.8, suitable for welding low-carbon steel and low-alloy high-strength structural steel, and performs particularly well in the manufacturing of LPG (liquefied petroleum gas) cylinders. It ensures a fast welding speed (up to more than 70m/h), easy slag removal, low spatter, and enhances the mechanical strength and corrosion resistance of the weld, applicable to industrial applications such as ships, boilers, and pressure vessels.