China SAW Wire EH14 Manufacturers, Suppliers, Factory

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for SAW Wire EH14,Welding wire EH14, We now have substantial goods source and also the rate is our advantage. Welcome to inquire about our merchandise.

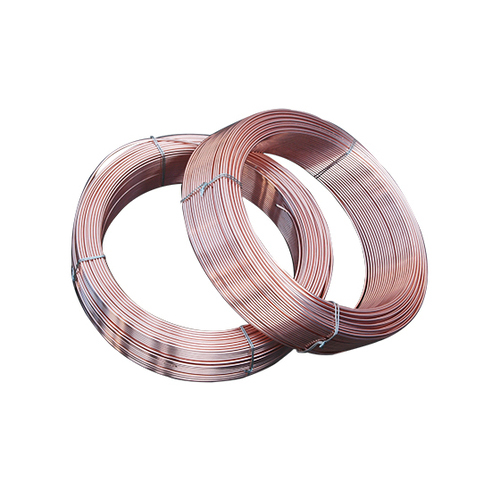

SAW Wire EH14, With more and more Chinese solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We've enough confidence to provide you both better items and service, because we have been more and more powerful, professional and experience in domestic and international.

Hot Products

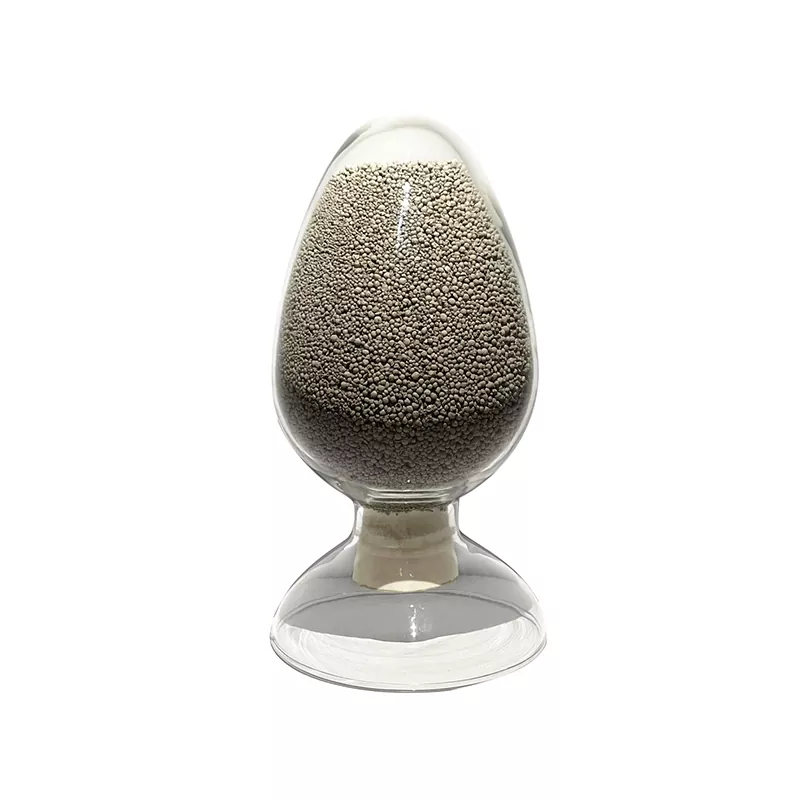

Welding flux SJ414

You can rest assured to buy customized Welding flux SJ414 from us. We look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!ER308L Stainless Steel

GUJIN® is one of the famous China ER308L Stainless Steel manufacturers and Stainless Steel suppliers.For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire Aws EL8

GUJIN® is a kind of low manganese low Submerged Arc Welding Wire Aws El8. It is matched with high manganese and high silicon type fluxes. Insensitive to rust on the base metal, excellent bead forming and slag separation. It is the most commonly used submerged arc welding wire. Monoles or dipoles. Can be used for AC/DC.Submerged Arc Welding Wire AWS EM12

Welcome to wholesale Submerged Arc Welding Wire AWS EM12 from us, every request from customers is being replied within 24 hours. GUJIN® is the professional manufacturer, we would like to provide you submerged arc welding wire and we will offer you the best after-sale service and timely delivery.Welding Wire EM13K

As the professional manufacture, GUJIN® would like to provide you Submerged Arc Welding Wire EM13K. For Submerged arc welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Submerged arc welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Submerged arc welding wire have characteristic design & practical performance & competitive price, for more information on the Submerged arc welding wire, please feel free to contact us.Welding flux SJ-503

With years of experience in production SJ-503, GUJIN can supply a wide range of submerged arc welding flux SJ-503. High quality submerged arc welding flux can meet many applications, if you need, please get our online timely service about submerged arc welding flux. In addition to the product list below, you can also customize your own unique submerged arc welding flux according to your specific needs.