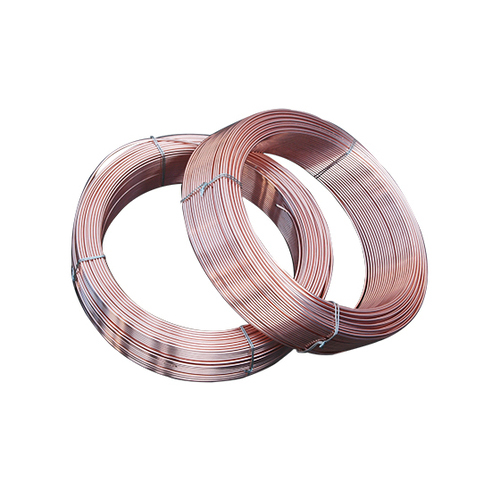

China ER308 welding wire Manufacturers, Suppliers, Factory

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for ER308 welding wire,ER308, We have been prepared to offer you the top suggestions on the designs of one's orders in a professional way if you need. During the meantime, we retain on developing new technologies and building new designs so as for making you ahead within the line of this business.

ER308 welding wire, Our technical expertise, customer-friendly service, and specialized products and solutions make us/company name the first choice of customers and vendors. We have been looking for your inquiry. Let's set up the cooperation right now!

Hot Products

Welding flux SJ101G

GUJIN® is a professional Welding flux SJ101G manufacturers and suppliers in China. If you interested in Submerged Arc welding flux SJ-101G products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.ER309L Stainless Steel

GUJIN® warmly welcome you to wholesale ER309L Stainless Steel from our factory. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire EH14

GUJIN® is a leading China Submerged Arc Welding Wire EH14 manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of products, so that our Submerged arc welding wire have been satisfied by many customers. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. Of course, also essential is our perfect after-sales service. If you are interested in our Submerged arc welding wire services, you can consult us now, we will reply to you in time!Aluminum Alloy Welding Wire

For Aluminum alloy welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our welding wire ER-5356 has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Aluminum alloy welding wire have characteristic design & practical performance & competitive price, for more information on the Aluminum alloy welding wire, please feel free to contact us.Sumberged Welding flux SJ-503

Our company has many years of SJ-503 production experience, can provide a wide range of Sumberged Welding flux SJ-503. High quality submerged arc welding fluxes can be used for a variety of applications. If you need them, please get our online service. In addition to the product list below, you can customize your own unique submerged arc welding flux to suit your specific needs.Welding flux GJ-101

GJ-101 submerged arc welding flux is a high-alkalinity sintered flux, specially designed for industrial welding applications to provide efficient and high-quality welding results. This fluoride-based flux has excellent slag removal performance, low impurity content (such as phosphorus and sulfur), and offers superior mechanical properties for carbon steel, low-alloy steel, and high-strength structural components. It is suitable for single-layer and multi-layer submerged arc welding (SAW), ensuring stable arc combustion, a beautiful weld appearance, and improving production efficiency in the manufacturing of pressure vessels, pipelines, and heavy machinery.