China Low-impurity welding materials Manufacturers, Suppliers, Factory

We've one of the most advanced generation tools, experienced and qualified engineers and workers, recognized good quality manage systems and a friendly skilled product sales workforce pre/after-sales support for Low-impurity welding materials,SJ101 Flux,Fluoride-alkaline type sintered flux,Submerged arc welding flux,High-strength steel flux, We warmly welcome clients from all around the world for almost any sort of cooperation with us to build a mutual advantage potential. We've been devoting ourselves wholeheartedly to supply consumers the very best company.

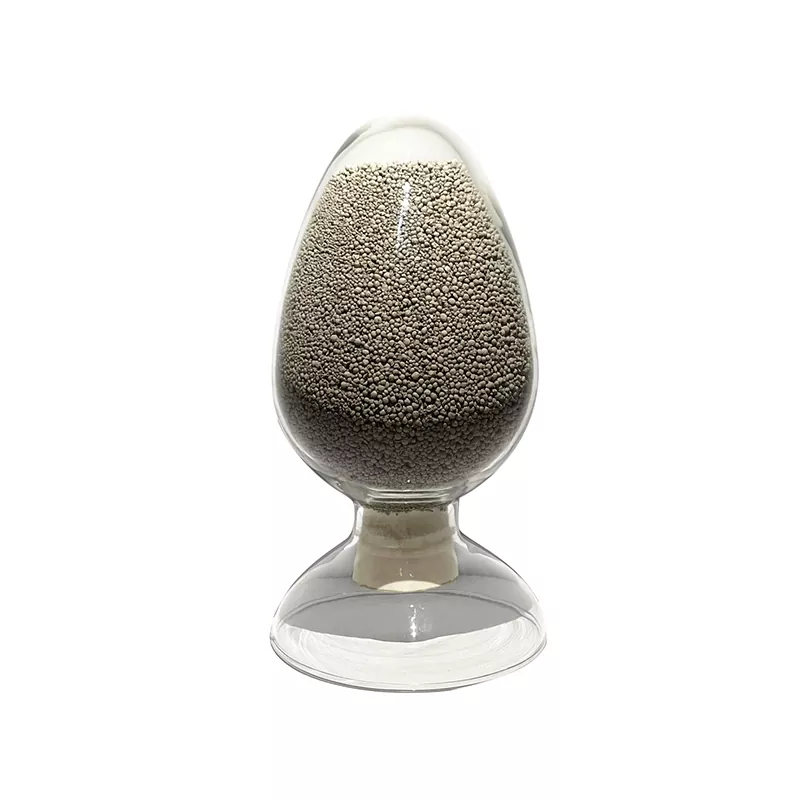

Low-impurity welding materials, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Hot Products

Welding flux SJ101G

GUJIN® is a professional Welding flux SJ101G manufacturers and suppliers in China. If you interested in Submerged Arc welding flux SJ-101G products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.Welding flux SJ601

As the professional manufacture, GUJIN® would like to provide you Welding flux SJ601. And GUJIN® will offer you the best after-sale service and timely delivery.ER309 Stainless Steel

GUJIN® is a professional ER309 Stainless Steel manufacturers and suppliers in China. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Welding Wire EM13K

As the professional manufacture, GUJIN® would like to provide you Submerged Arc Welding Wire EM13K. For Submerged arc welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Submerged arc welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Submerged arc welding wire have characteristic design & practical performance & competitive price, for more information on the Submerged arc welding wire, please feel free to contact us.Welding flux SJ-503

With years of experience in production SJ-503, GUJIN can supply a wide range of submerged arc welding flux SJ-503. High quality submerged arc welding flux can meet many applications, if you need, please get our online timely service about submerged arc welding flux. In addition to the product list below, you can also customize your own unique submerged arc welding flux according to your specific needs.Submerged Arc Welding Flux AN-60

Submerged Arc Welding Flux AN-60 is a high-performance, agglomerated flux designed for efficient welding of carbon and low-alloy steels, such as Q345, 16Mn, Q390, and 15MnV. This neutral to active flux offers excellent slag detachability, smooth bead appearance, and superior weld metal integrity, making it ideal for automatic and semi-automatic submerged arc welding processes. Compatible with wires like EL12, EM12K, and Sv-08A, AN-60 ensures high deposition rates and minimal spatter, enhancing productivity in structural fabrication, shipbuilding, and pressure vessel manufacturing.