China SJ101 Flux Manufacturers, Suppliers, Factory

We know that we only thrive if we can guarantee our combined price competiveness and quality advantageous at the same time for SJ101 Flux,Fluoride-alkaline type sintered flux,Submerged arc welding flux,High-strength steel flux,Low-impurity welding materials, We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

SJ101 Flux, All styles appear on our website are for customizing. We meet up to private requirements with all items of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Hot Products

Welding flux SJ107

GUJIN® is a professional Submerged Arc welding flux SJ107 manufacturers and suppliers in China, you can rest assured to wholesale and customized Welding flux SJ107 from our factory and we will offer you the best after-sale service and timely delivery.Welding flux SJ101G

GUJIN® is a professional Welding flux SJ101G manufacturers and suppliers in China. If you interested in Submerged Arc welding flux SJ-101G products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.ER70S-6 Stainless Steel

GUJIN® is a professional ER70S-6 Stainless Steel manufacturers and suppliers in China. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding flux SJ-501 A

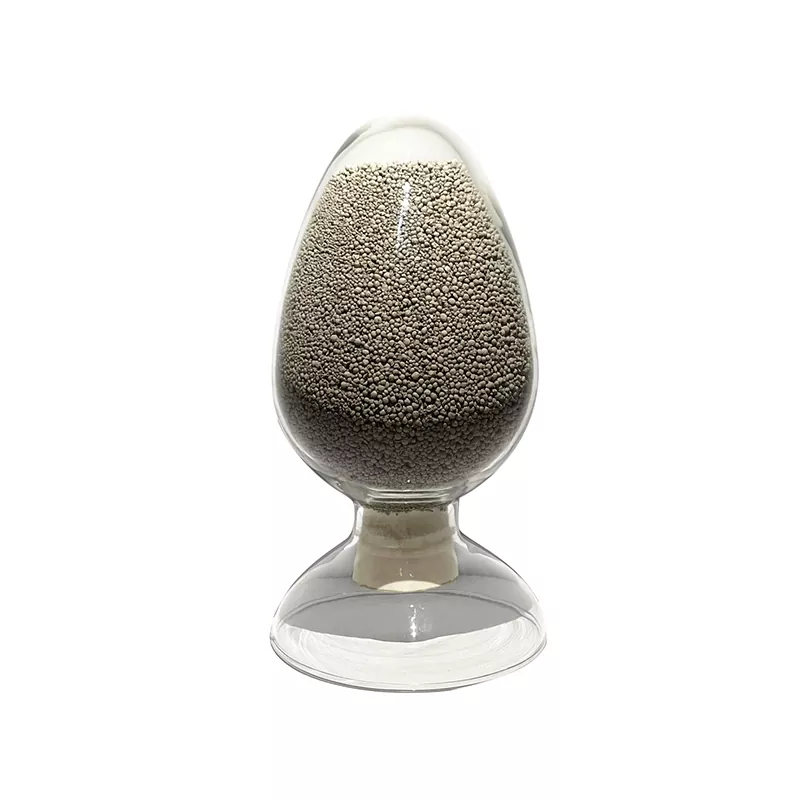

Submerged Arc Welding Flux SJ-501 A is a high-performance agglomerated aluminum-rutile type acid sintered flux with a basicity index of approximately 0.5-0.93 and a particle size of 10-60 mesh (about 0.3-2.0mm). It is specially designed for low-alloy steels and high-strength steels (such as ASTM A514, A517), supporting single-wire or multi-wire high-speed welding (up to 100m/h), and is suitable for applications such as small cylinders, LPG tanks, pressure vessels, and shipbuilding. This flux complies with the standards of EN760 SA AR 1 88 AC H5 and AWS A5.17/5.23 F7A0-EL12, providing stable arc, excellent slag detachability, smooth weld seams, and resistance to cracks and pores. It is not sensitive to surface rust and scale, ensuring efficient welding quality and excellent mechanical properties, such as high impact toughness and tensile strength.LPG Cylinder Welding Flux

SJ-501 submerged arc welding flux is an active aluminum-titanium type acidic sintered flux, designed for high-efficiency welding, providing stable arc combustion and excellent weld quality. The basicity index of this flux is approximately 0.5-0.8, suitable for welding low-carbon steel and low-alloy high-strength structural steel, and performs particularly well in the manufacturing of LPG (liquefied petroleum gas) cylinders. It ensures a fast welding speed (up to more than 70m/h), easy slag removal, low spatter, and enhances the mechanical strength and corrosion resistance of the weld, applicable to industrial applications such as ships, boilers, and pressure vessels.Special submerged arc welding flux for gas cylinders

SJ-501 submerged arc welding flux is an active aluminum-titanium type acidic sintered flux, designed for high-efficiency welding, providing stable arc combustion and excellent weld quality. The basicity index of this flux is approximately 0.5-0.8, suitable for welding low-carbon steel and low-alloy high-strength structural steel, and performs particularly well in the manufacturing of LPG (liquefied petroleum gas) cylinders. It ensures a fast welding speed (up to more than 70m/h), easy slag removal, low spatter, and enhances the mechanical strength and corrosion resistance of the weld, applicable to industrial applications such as ships, boilers, and pressure vessels.