China Sj301 Agglomerated Flux Welding Flux Manufacturers, Suppliers, Factory

Our solutions are greatly recognized and reliable by customers and will fulfill continuously altering financial and social requirements for Sj301 Agglomerated Flux Welding Flux,Welding Flux Sj501,Welding Flux,MIG Welding Flux Core,LPG Cylinder Welding Flux, Our enterprise warmly welcome close friends from everywhere in the environment to go to, examine and negotiate organization.

Sj301 Agglomerated Flux Welding Flux, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Hot Products

ER309 Stainless Steel

GUJIN® is a professional ER309 Stainless Steel manufacturers and suppliers in China. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire AWS EM12K

GUJIN® is a professional Submerged Arc Welding Wire AWS EM12K manufacturers and suppliers in China, you can rest assured to wholesale and customized submerged arc welding wire from our factory and we will offer you the best after-sale service and timely delivery.Sumberged Welding flux SJ-503

Our company has many years of SJ-503 production experience, can provide a wide range of Sumberged Welding flux SJ-503. High quality submerged arc welding fluxes can be used for a variety of applications. If you need them, please get our online service. In addition to the product list below, you can customize your own unique submerged arc welding flux to suit your specific needs.Special submerged arc welding flux for gas cylinders

SJ-501 submerged arc welding flux is an active aluminum-titanium type acidic sintered flux, designed for high-efficiency welding, providing stable arc combustion and excellent weld quality. The basicity index of this flux is approximately 0.5-0.8, suitable for welding low-carbon steel and low-alloy high-strength structural steel, and performs particularly well in the manufacturing of LPG (liquefied petroleum gas) cylinders. It ensures a fast welding speed (up to more than 70m/h), easy slag removal, low spatter, and enhances the mechanical strength and corrosion resistance of the weld, applicable to industrial applications such as ships, boilers, and pressure vessels.high-performance agglomerated calcium-silicate flux-SJ-301

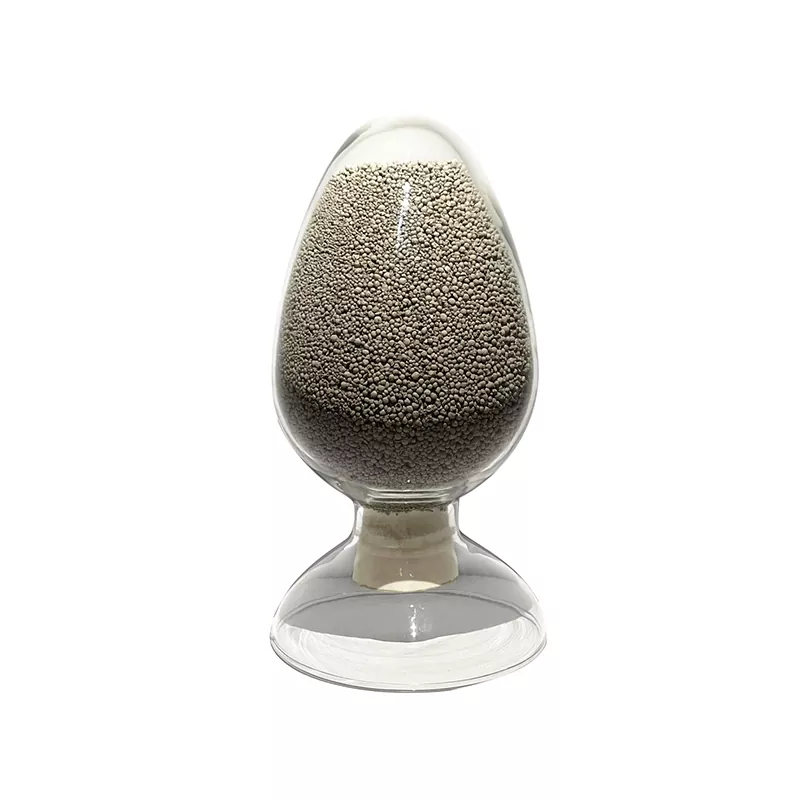

SJ301 submerged arc welding flux is a high-performance agglomerated calcium-silicate flux designed for efficient welding of low-carbon and low-alloy steels. With a neutral basicity index of 1.0, it delivers stable arc performance, effortless slag detachment, and superior weld bead aesthetics, making it ideal for high-speed applications in industries like pipeline construction, bridge building, and machinery fabrication. Certified under AWS A5.17 F6A0-EL8 and F7A2-EM12K standards, this flux minimizes porosity and ensures strong mechanical properties, such as tensile strength up to 670 MPa when paired with EM12K wire. As a reliable choice from Chinese manufacturers, SJ301 enhances productivity by supporting AC/DC currents and multi-layer welding without interface defects. Perfect for structural projects requiring durability and cost-efficiency.SJ101 Fluorine-alkaline type sintered flux

SJ101 is an advanced fluorine-alkaline type sintered flux, specifically designed for submerged arc welding processes, offering an excellent welding experience. Whether for single-layer or multi-layer welding, it ensures a stable arc, easy slag removal, and smooth weld formation. It is particularly suitable for carbon steel and low-alloy steel structural components, such as oil storage tanks and bridge components. The low-impurity formula reduces weld defects, enhances impact resistance and mechanical properties, and supports AC/DC current operation with uniform particle size (10-60 mesh). Unlike traditional fluxes, SJ101 has optimized alkalinity (approximately 1.8), reducing spatter and improving production efficiency. GJFlux is committed to high-quality welding materials, ensuring that SJ101 meets international standards (such as AWS), helping you reduce costs and enhance project reliability. Choose SJ101 now to unlock a new realm of efficient welding!