China Agglomerated Submerged Arc Welding Flux SJ101 Manufacturers, Suppliers, Factory

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Agglomerated Submerged Arc Welding Flux SJ101,Submerged Welding Flux SJ101,Melting Flux,Adhesive Flux,Sintered Flux, Sincerely hope we're increasing up along with our buyers all around the entire world.

Agglomerated Submerged Arc Welding Flux SJ101, All styles appear on our website are for customizing. We meet up to individual requirements with all solutions of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Hot Products

Welding flux SJ101G

GUJIN® is a professional Welding flux SJ101G manufacturers and suppliers in China. If you interested in Submerged Arc welding flux SJ-101G products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.Welding flux SJ301

For agglomerated submerged arc welding flux SJ-301, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Welding flux SJ301 has been well received by many customers and enjoyed a good reputation in many countries. The GUJIN ® SJ-301 has a better quality level, better performance for use, and a below-market price, for more information on the SJ-301, please feel free to contact us.ER309 Stainless Steel

GUJIN® is a professional ER309 Stainless Steel manufacturers and suppliers in China. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.ER309L Stainless Steel

GUJIN® warmly welcome you to wholesale ER309L Stainless Steel from our factory. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire Aws EL8

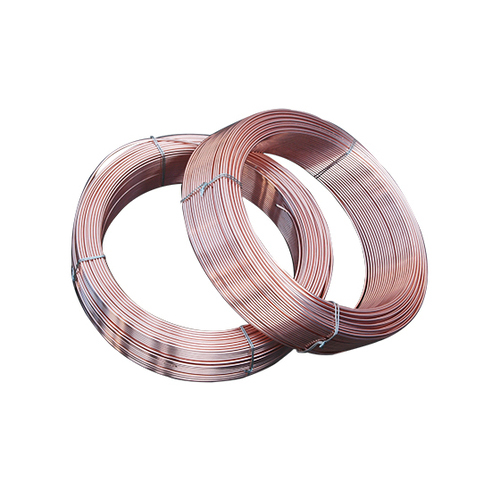

GUJIN® is a kind of low manganese low Submerged Arc Welding Wire Aws El8. It is matched with high manganese and high silicon type fluxes. Insensitive to rust on the base metal, excellent bead forming and slag separation. It is the most commonly used submerged arc welding wire. Monoles or dipoles. Can be used for AC/DC.Submerged Welding flux SJ-101

The Submerged Welding flux SJ-101 produced by GUJIN® is the perfect choice for all your industrial needs. We are a reliable and trustworthy manufacturer that offers high quality products at favorable prices. As a wholesale supplier of SJ-101 fluxes, we are committed to providing you with the best products and best customer service.