China Welding wire EM12 Manufacturers, Suppliers, Factory

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Welding wire EM12,SAW Wire EM12, Our corporation is dedicated to giving customers with superior and secure excellent items at competitive rate, creating just about every customer content with our services and products.

Welding wire EM12, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We're looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

Hot Products

ER308L Stainless Steel

GUJIN® is one of the famous China ER308L Stainless Steel manufacturers and Stainless Steel suppliers.For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire AWS EM12

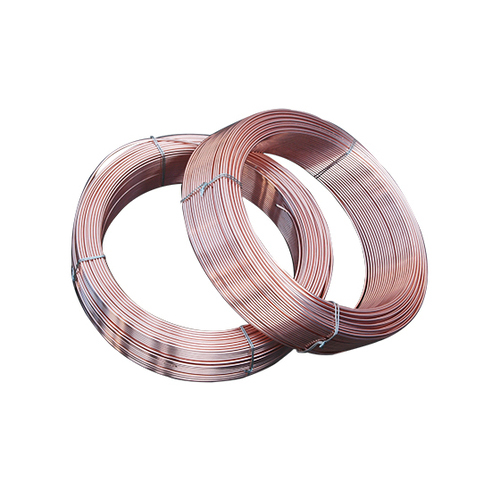

Welcome to wholesale Submerged Arc Welding Wire AWS EM12 from us, every request from customers is being replied within 24 hours. GUJIN® is the professional manufacturer, we would like to provide you submerged arc welding wire and we will offer you the best after-sale service and timely delivery.Submerged Arc Welding Wire EH14

GUJIN® is a leading China Submerged Arc Welding Wire EH14 manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of products, so that our Submerged arc welding wire have been satisfied by many customers. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. Of course, also essential is our perfect after-sales service. If you are interested in our Submerged arc welding wire services, you can consult us now, we will reply to you in time!Welding Wire EM13K

As the professional manufacture, GUJIN® would like to provide you Submerged Arc Welding Wire EM13K. For Submerged arc welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Submerged arc welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Submerged arc welding wire have characteristic design & practical performance & competitive price, for more information on the Submerged arc welding wire, please feel free to contact us.Aluminum Alloy Welding Wire

For Aluminum alloy welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our welding wire ER-5356 has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Aluminum alloy welding wire have characteristic design & practical performance & competitive price, for more information on the Aluminum alloy welding wire, please feel free to contact us.Submerged Arc Welding flux SJ-501 A

Submerged Arc Welding Flux SJ-501 A is a high-performance agglomerated aluminum-rutile type acid sintered flux with a basicity index of approximately 0.5-0.93 and a particle size of 10-60 mesh (about 0.3-2.0mm). It is specially designed for low-alloy steels and high-strength steels (such as ASTM A514, A517), supporting single-wire or multi-wire high-speed welding (up to 100m/h), and is suitable for applications such as small cylinders, LPG tanks, pressure vessels, and shipbuilding. This flux complies with the standards of EN760 SA AR 1 88 AC H5 and AWS A5.17/5.23 F7A0-EL12, providing stable arc, excellent slag detachability, smooth weld seams, and resistance to cracks and pores. It is not sensitive to surface rust and scale, ensuring efficient welding quality and excellent mechanical properties, such as high impact toughness and tensile strength.