China Agglomerated submerged arc welding flux SJ107 Manufacturers, Suppliers, Factory

We stick with the theory of "quality very first, support 1st, continual improvement and innovation to fulfill the customers" for that management and "zero defect, zero complaints" as the quality objective. To excellent our company, we provide the merchandise together with the great good quality at the reasonable cost for Agglomerated submerged arc welding flux SJ107,SJ107 Welding flux, We hope we could have a helpful romantic relationship with businessman from all over the globe.

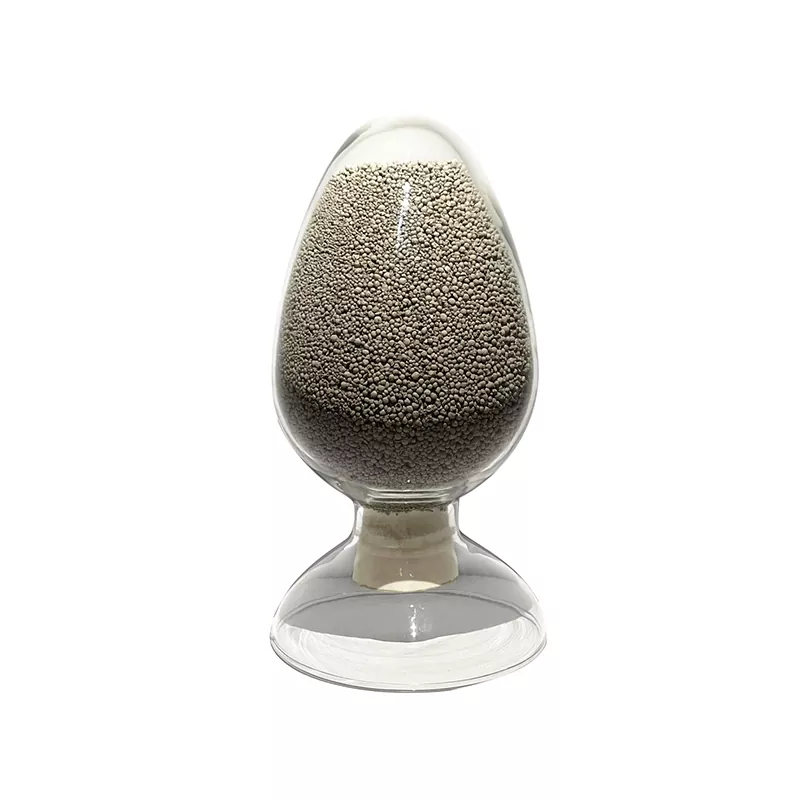

Agglomerated submerged arc welding flux SJ107, Taking the core concept of "to be the Responsible". We will redound up on society for high quality solutions and good service. We are going to initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Hot Products

Welding flux SJ101

GUJIN® is Welding flux SJ101 manufacturers and suppliers in China who can wholesale Welding flux SJ101, we can provide professional service and better price for you.Welding flux SJ107

GUJIN® is a professional Submerged Arc welding flux SJ107 manufacturers and suppliers in China, you can rest assured to wholesale and customized Welding flux SJ107 from our factory and we will offer you the best after-sale service and timely delivery.ER308L Stainless Steel

GUJIN® is one of the famous China ER308L Stainless Steel manufacturers and Stainless Steel suppliers.For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire Aws EL8

GUJIN® is a kind of low manganese low Submerged Arc Welding Wire Aws El8. It is matched with high manganese and high silicon type fluxes. Insensitive to rust on the base metal, excellent bead forming and slag separation. It is the most commonly used submerged arc welding wire. Monoles or dipoles. Can be used for AC/DC.Submerged Arc Welding Wire AWS EM12

Welcome to wholesale Submerged Arc Welding Wire AWS EM12 from us, every request from customers is being replied within 24 hours. GUJIN® is the professional manufacturer, we would like to provide you submerged arc welding wire and we will offer you the best after-sale service and timely delivery.SJ101 Fluorine-alkaline type sintered flux

SJ101 is an advanced fluorine-alkaline type sintered flux, specifically designed for submerged arc welding processes, offering an excellent welding experience. Whether for single-layer or multi-layer welding, it ensures a stable arc, easy slag removal, and smooth weld formation. It is particularly suitable for carbon steel and low-alloy steel structural components, such as oil storage tanks and bridge components. The low-impurity formula reduces weld defects, enhances impact resistance and mechanical properties, and supports AC/DC current operation with uniform particle size (10-60 mesh). Unlike traditional fluxes, SJ101 has optimized alkalinity (approximately 1.8), reducing spatter and improving production efficiency. GJFlux is committed to high-quality welding materials, ensuring that SJ101 meets international standards (such as AWS), helping you reduce costs and enhance project reliability. Choose SJ101 now to unlock a new realm of efficient welding!