China Agglomerated submerged arc welding flux SJ301 Manufacturers, Suppliers, Factory

We're convinced that with joint initiatives, the business between us will bring us mutual benefits. We can easily guarantee you merchandise good quality and competitive rate for Agglomerated submerged arc welding flux SJ301,SJ301 Welding flux,SJ301,Pipeline welding flux SJ301,Steel structure welding flux, As an expert specialized within this field, we've been committed to solving any problem of high temperature protection for users.

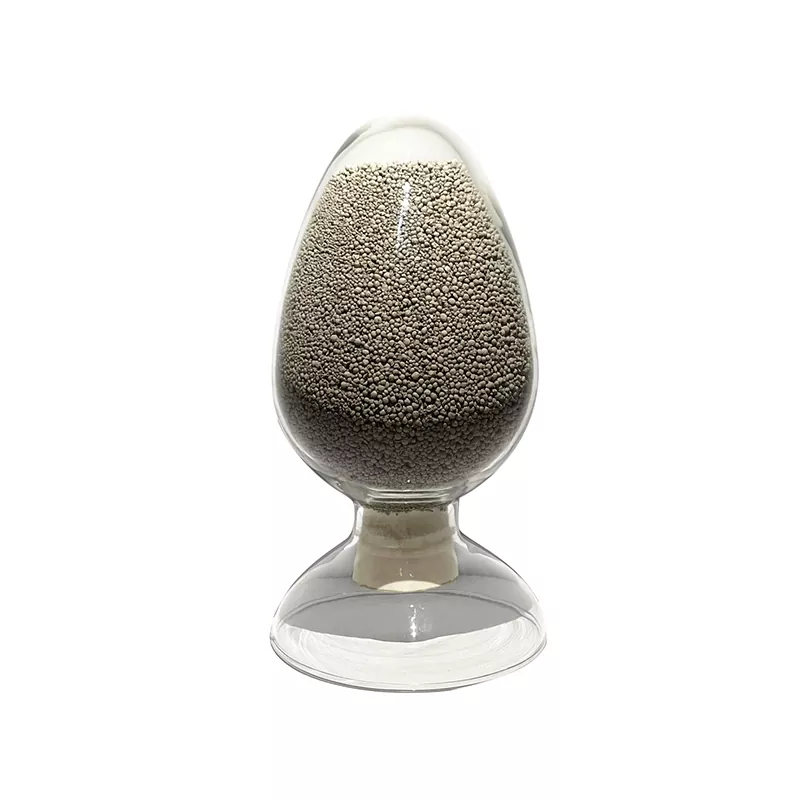

Agglomerated submerged arc welding flux SJ301, During the development, our company has built a well-known brand. It is well highly acclaimed by our customers. OEM and ODM are accepted. We've been looking forward to customers from all over the world to join us to a wild cooperation.

Hot Products

ER309 Stainless Steel

GUJIN® is a professional ER309 Stainless Steel manufacturers and suppliers in China. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Submerged Arc Welding Wire AWS EM12K

GUJIN® is a professional Submerged Arc Welding Wire AWS EM12K manufacturers and suppliers in China, you can rest assured to wholesale and customized submerged arc welding wire from our factory and we will offer you the best after-sale service and timely delivery.Aluminum Alloy Welding Wire

For Aluminum alloy welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our welding wire ER-5356 has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Aluminum alloy welding wire have characteristic design & practical performance & competitive price, for more information on the Aluminum alloy welding wire, please feel free to contact us.Welding flux GJ-101

GJ-101 submerged arc welding flux is a high-alkalinity sintered flux, specially designed for industrial welding applications to provide efficient and high-quality welding results. This fluoride-based flux has excellent slag removal performance, low impurity content (such as phosphorus and sulfur), and offers superior mechanical properties for carbon steel, low-alloy steel, and high-strength structural components. It is suitable for single-layer and multi-layer submerged arc welding (SAW), ensuring stable arc combustion, a beautiful weld appearance, and improving production efficiency in the manufacturing of pressure vessels, pipelines, and heavy machinery.high-performance agglomerated calcium-silicate flux-SJ-301

SJ301 submerged arc welding flux is a high-performance agglomerated calcium-silicate flux designed for efficient welding of low-carbon and low-alloy steels. With a neutral basicity index of 1.0, it delivers stable arc performance, effortless slag detachment, and superior weld bead aesthetics, making it ideal for high-speed applications in industries like pipeline construction, bridge building, and machinery fabrication. Certified under AWS A5.17 F6A0-EL8 and F7A2-EM12K standards, this flux minimizes porosity and ensures strong mechanical properties, such as tensile strength up to 670 MPa when paired with EM12K wire. As a reliable choice from Chinese manufacturers, SJ301 enhances productivity by supporting AC/DC currents and multi-layer welding without interface defects. Perfect for structural projects requiring durability and cost-efficiency.Submerged Arc Welding Flux AN-60

Submerged Arc Welding Flux AN-60 is a high-performance, agglomerated flux designed for efficient welding of carbon and low-alloy steels, such as Q345, 16Mn, Q390, and 15MnV. This neutral to active flux offers excellent slag detachability, smooth bead appearance, and superior weld metal integrity, making it ideal for automatic and semi-automatic submerged arc welding processes. Compatible with wires like EL12, EM12K, and Sv-08A, AN-60 ensures high deposition rates and minimal spatter, enhancing productivity in structural fabrication, shipbuilding, and pressure vessel manufacturing.