China Steel structure welding flux Manufacturers, Suppliers, Factory

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Steel structure welding flux,Agglomerated submerged arc welding flux SJ301,SJ301 Welding flux,SJ301,Pipeline welding flux SJ301, Should you pursuit the Hi-quality, Hi-stable, Aggressive price tag parts, business name is your most effective choice!

Steel structure welding flux, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our items are the best. Once Selected, Perfect Forever!

Hot Products

Welding flux SJ102

As the professional manufacture, GUJIN® would like to provide you Welding flux SJ102. And GUJIN® will offer you the best after-sale service and timely delivery.Welding flux SJ107

GUJIN® is a professional Submerged Arc welding flux SJ107 manufacturers and suppliers in China, you can rest assured to wholesale and customized Welding flux SJ107 from our factory and we will offer you the best after-sale service and timely delivery.Welding flux SJ414

You can rest assured to buy customized Welding flux SJ414 from us. We look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!Submerged Arc Welding Wire Aws EL8

GUJIN® is a kind of low manganese low Submerged Arc Welding Wire Aws El8. It is matched with high manganese and high silicon type fluxes. Insensitive to rust on the base metal, excellent bead forming and slag separation. It is the most commonly used submerged arc welding wire. Monoles or dipoles. Can be used for AC/DC.Aluminum Alloy Welding Wire

For Aluminum alloy welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our welding wire ER-5356 has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Aluminum alloy welding wire have characteristic design & practical performance & competitive price, for more information on the Aluminum alloy welding wire, please feel free to contact us.high-performance agglomerated calcium-silicate flux-SJ-301

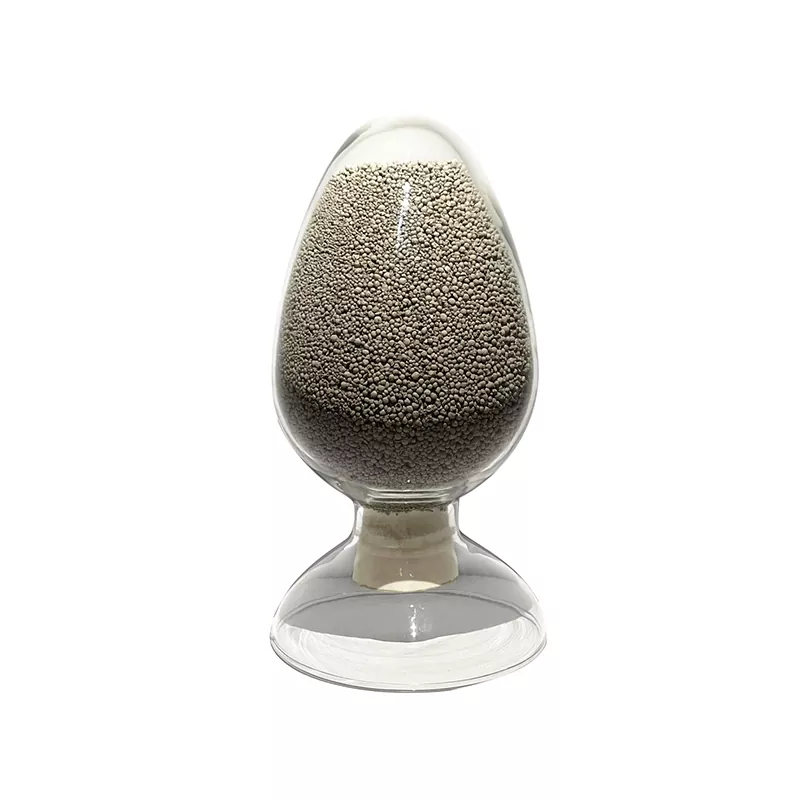

SJ301 submerged arc welding flux is a high-performance agglomerated calcium-silicate flux designed for efficient welding of low-carbon and low-alloy steels. With a neutral basicity index of 1.0, it delivers stable arc performance, effortless slag detachment, and superior weld bead aesthetics, making it ideal for high-speed applications in industries like pipeline construction, bridge building, and machinery fabrication. Certified under AWS A5.17 F6A0-EL8 and F7A2-EM12K standards, this flux minimizes porosity and ensures strong mechanical properties, such as tensile strength up to 670 MPa when paired with EM12K wire. As a reliable choice from Chinese manufacturers, SJ301 enhances productivity by supporting AC/DC currents and multi-layer welding without interface defects. Perfect for structural projects requiring durability and cost-efficiency.