China Steel structure welding flux SJ301 Manufacturers, Suppliers, Factory

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for Steel structure welding flux SJ301,Agglomerated submerged arc welding flux SJ301,SJ301 Welding flux,SJ301,Pipeline welding flux SJ301, We welcome new and aged shoppers from all walks of daily life to call us for long term business associations and mutual accomplishment!

Steel structure welding flux SJ301, Further, we're supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to provide our clients an effective range of products and solutions.

Hot Products

Welding flux SJ501

GUJIN® is a leading manufacturer, supplier, and exporter of Welding flux SJ501 in China. Adhering to the pursuit of perfect product quality has led to the satisfaction of many customers for our SJ-501. High quality raw materials and competitive prices are what every customer wants, which we can provide to you. Of course, our perfect after-sales service is also very important. If you are interested in our Submerged Arc Flux SJ501 product, you can consult us now and we will reply to you promptly!Submerged Arc Welding Wire AWS EM12

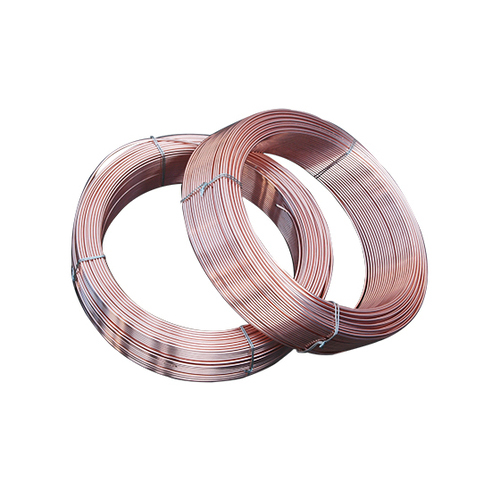

Welcome to wholesale Submerged Arc Welding Wire AWS EM12 from us, every request from customers is being replied within 24 hours. GUJIN® is the professional manufacturer, we would like to provide you submerged arc welding wire and we will offer you the best after-sale service and timely delivery.Submerged Arc Welding Wire EH14

GUJIN® is a leading China Submerged Arc Welding Wire EH14 manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of products, so that our Submerged arc welding wire have been satisfied by many customers. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. Of course, also essential is our perfect after-sales service. If you are interested in our Submerged arc welding wire services, you can consult us now, we will reply to you in time!Aluminum Alloy Welding Wire

For Aluminum alloy welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our welding wire ER-5356 has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Aluminum alloy welding wire have characteristic design & practical performance & competitive price, for more information on the Aluminum alloy welding wire, please feel free to contact us.ER70S-6 Stainless Steel

GUJIN® is a professional ER70S-6 Stainless Steel manufacturers and suppliers in China. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.high-performance agglomerated calcium-silicate flux-SJ-301

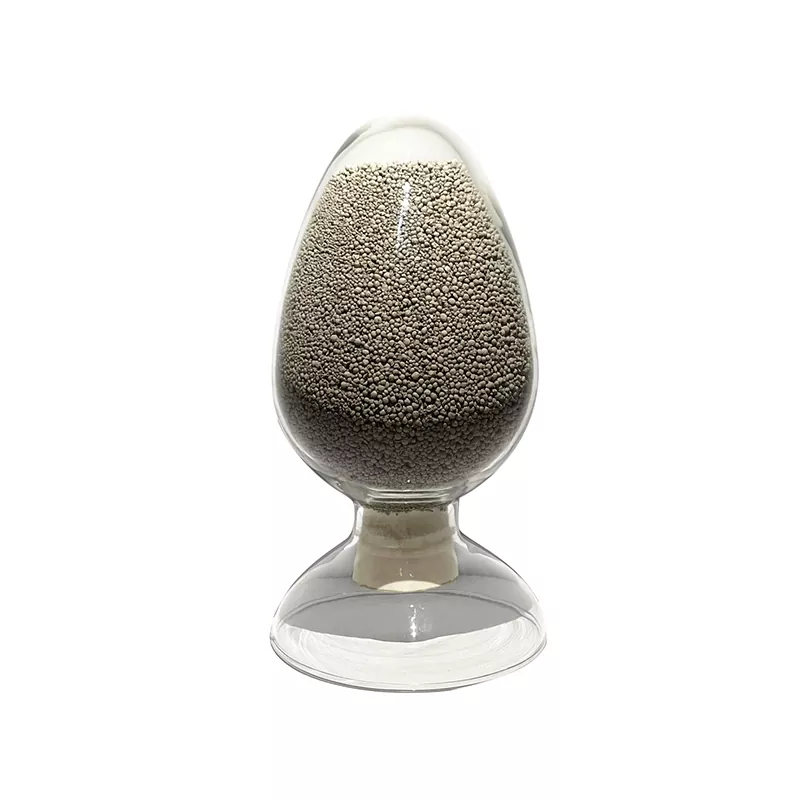

SJ301 submerged arc welding flux is a high-performance agglomerated calcium-silicate flux designed for efficient welding of low-carbon and low-alloy steels. With a neutral basicity index of 1.0, it delivers stable arc performance, effortless slag detachment, and superior weld bead aesthetics, making it ideal for high-speed applications in industries like pipeline construction, bridge building, and machinery fabrication. Certified under AWS A5.17 F6A0-EL8 and F7A2-EM12K standards, this flux minimizes porosity and ensures strong mechanical properties, such as tensile strength up to 670 MPa when paired with EM12K wire. As a reliable choice from Chinese manufacturers, SJ301 enhances productivity by supporting AC/DC currents and multi-layer welding without interface defects. Perfect for structural projects requiring durability and cost-efficiency.