China LNG Welding Flux Manufacturers, Suppliers, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for LNG Welding Flux,Agglomerated Submerged Arc Welding Flux SJ601,SJ601 Welding Flux,SJ601,Petroleum And Petrochemical Specific Welding Flux, In case you are intrigued in any of our products or want to focus on a personalized get, please sense totally free to contact us. We're wanting ahead to forming successful enterprise relationships with new shoppers across the world during the in close proximity to long term.

LNG Welding Flux, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Hot Products

Welding flux SJ101G

GUJIN® is a professional Welding flux SJ101G manufacturers and suppliers in China. If you interested in Submerged Arc welding flux SJ-101G products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.Welding flux SJ601

As the professional manufacture, GUJIN® would like to provide you Welding flux SJ601. And GUJIN® will offer you the best after-sale service and timely delivery.ER308 Stainless Steel

GUJIN® as the professional manufacturer, we would like to provide you ER308 Stainless Steel. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.ER309L Stainless Steel

GUJIN® warmly welcome you to wholesale ER309L Stainless Steel from our factory. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Aluminum Alloy Welding Wire

For Aluminum alloy welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our welding wire ER-5356 has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Aluminum alloy welding wire have characteristic design & practical performance & competitive price, for more information on the Aluminum alloy welding wire, please feel free to contact us.Submerged Arc Welding flux SJ-501 A

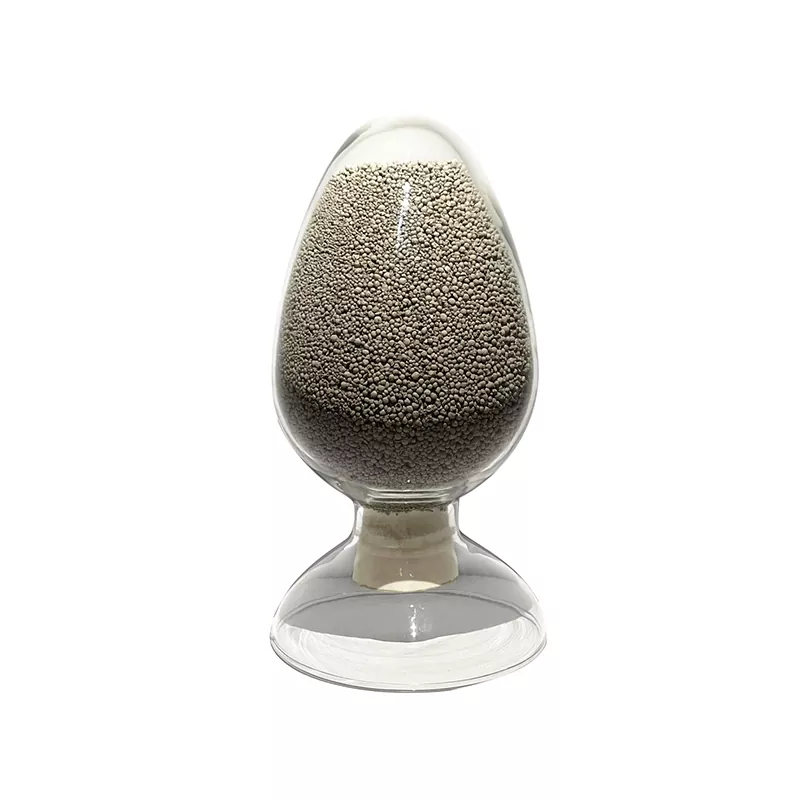

Submerged Arc Welding Flux SJ-501 A is a high-performance agglomerated aluminum-rutile type acid sintered flux with a basicity index of approximately 0.5-0.93 and a particle size of 10-60 mesh (about 0.3-2.0mm). It is specially designed for low-alloy steels and high-strength steels (such as ASTM A514, A517), supporting single-wire or multi-wire high-speed welding (up to 100m/h), and is suitable for applications such as small cylinders, LPG tanks, pressure vessels, and shipbuilding. This flux complies with the standards of EN760 SA AR 1 88 AC H5 and AWS A5.17/5.23 F7A0-EL12, providing stable arc, excellent slag detachability, smooth weld seams, and resistance to cracks and pores. It is not sensitive to surface rust and scale, ensuring efficient welding quality and excellent mechanical properties, such as high impact toughness and tensile strength.