China Welding Wire Manufacturers, Suppliers, Factory

To consistently enhance the management method by virtue of the rule of ""sincerely, fantastic religion and top quality are the base of business development"", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for Welding Wire,MIG Welding Wire Welding Consumables,Welding Consumable Er5356 Welding Wire,MIG Welding Wire Welding Material,Welding Electrode, Now we now have established steady and lengthy company associations with clients from North America, Western Europe, Africa, South America, extra than 60 countries and regions.

Welding Wire, We warmly welcome your patronage and will serve our clients both at home and abroad with items of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Hot Products

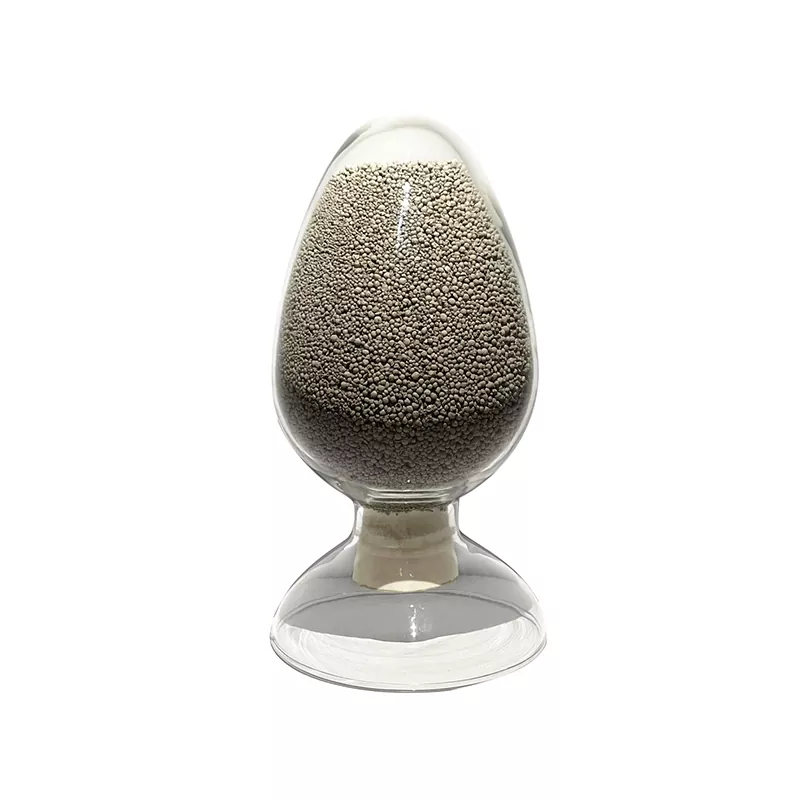

Welding flux SJ414

You can rest assured to buy customized Welding flux SJ414 from us. We look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!Welding flux SJ612

GUJIN® warmly welcome you to wholesale Welding flux SJ612 from our factory. Our products are CE certified and currently have a large amount of factory inventory. We will provide you with good service and factory discounted prices.ER309L Stainless Steel

GUJIN® warmly welcome you to wholesale ER309L Stainless Steel from our factory. For Stainless steel welding wire, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Stainless steel welding wire has been well received by many customers and enjoyed a good reputation in many countries. GUJIN® Stainless steel welding wire have characteristic design & practical performance & competitive price, for more information on the Stainless steel welding wire, please feel free to contact us.Sumberged Welding flux SJ-503

Our company has many years of SJ-503 production experience, can provide a wide range of Sumberged Welding flux SJ-503. High quality submerged arc welding fluxes can be used for a variety of applications. If you need them, please get our online service. In addition to the product list below, you can customize your own unique submerged arc welding flux to suit your specific needs.Welding flux GJ-101

GJ-101 submerged arc welding flux is a high-alkalinity sintered flux, specially designed for industrial welding applications to provide efficient and high-quality welding results. This fluoride-based flux has excellent slag removal performance, low impurity content (such as phosphorus and sulfur), and offers superior mechanical properties for carbon steel, low-alloy steel, and high-strength structural components. It is suitable for single-layer and multi-layer submerged arc welding (SAW), ensuring stable arc combustion, a beautiful weld appearance, and improving production efficiency in the manufacturing of pressure vessels, pipelines, and heavy machinery.LPG Cylinder Welding Flux

SJ-501 submerged arc welding flux is an active aluminum-titanium type acidic sintered flux, designed for high-efficiency welding, providing stable arc combustion and excellent weld quality. The basicity index of this flux is approximately 0.5-0.8, suitable for welding low-carbon steel and low-alloy high-strength structural steel, and performs particularly well in the manufacturing of LPG (liquefied petroleum gas) cylinders. It ensures a fast welding speed (up to more than 70m/h), easy slag removal, low spatter, and enhances the mechanical strength and corrosion resistance of the weld, applicable to industrial applications such as ships, boilers, and pressure vessels.